Provide users with "one-stop" service complete application solutions, consulting, planning, product, training, technical support and after-sales service. Respond quickly to customers and improve service quality.

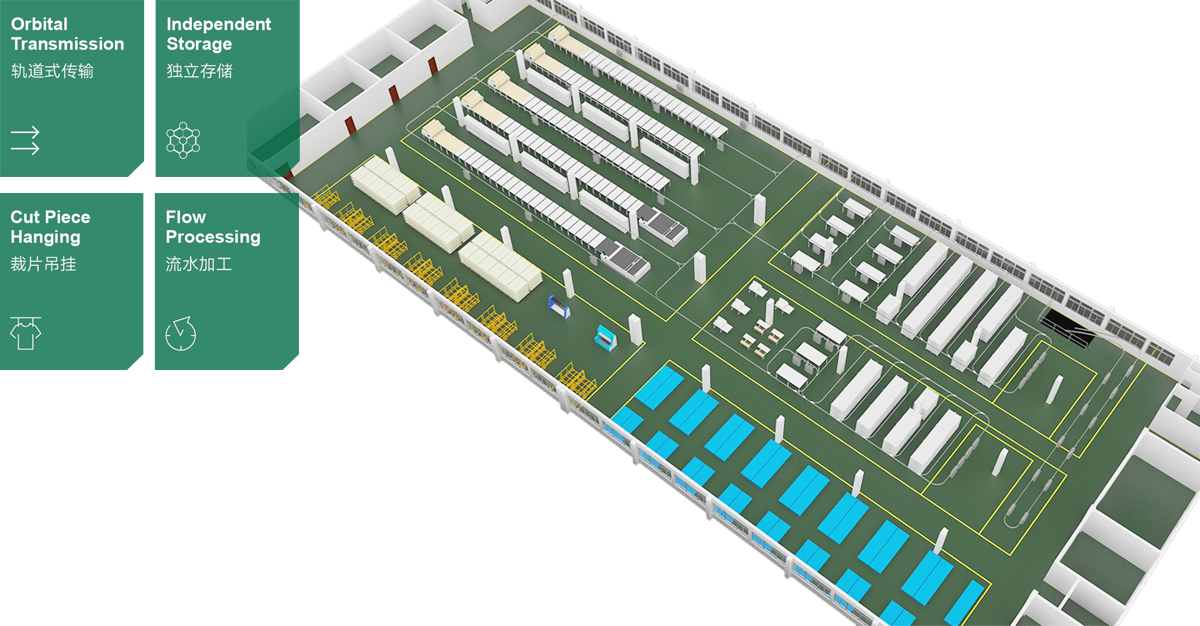

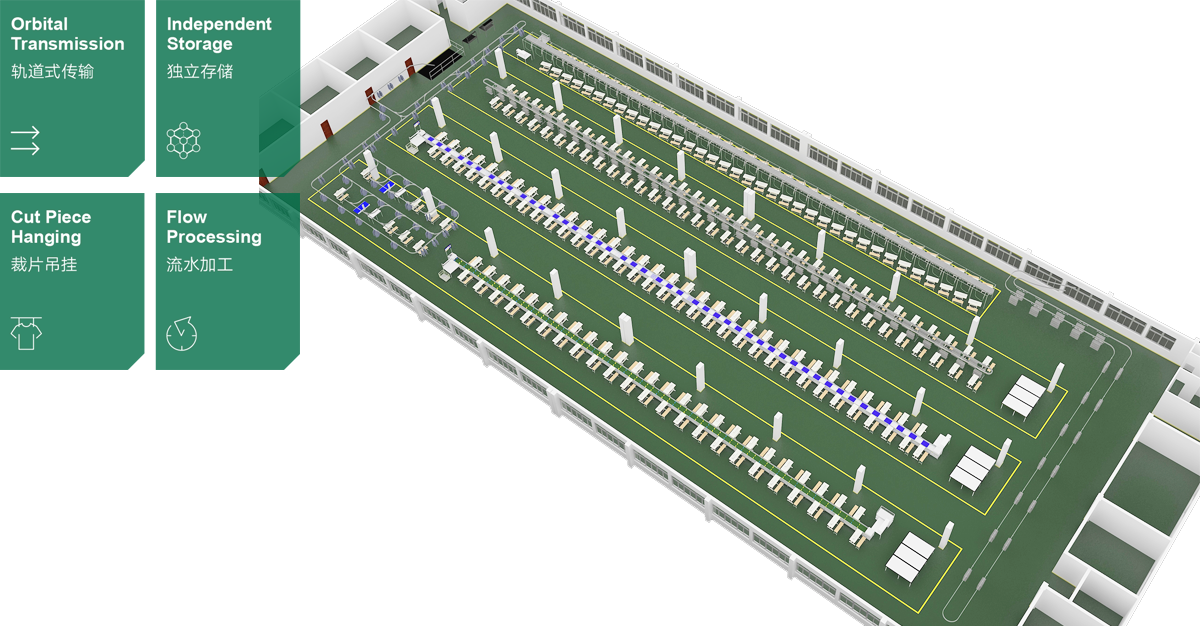

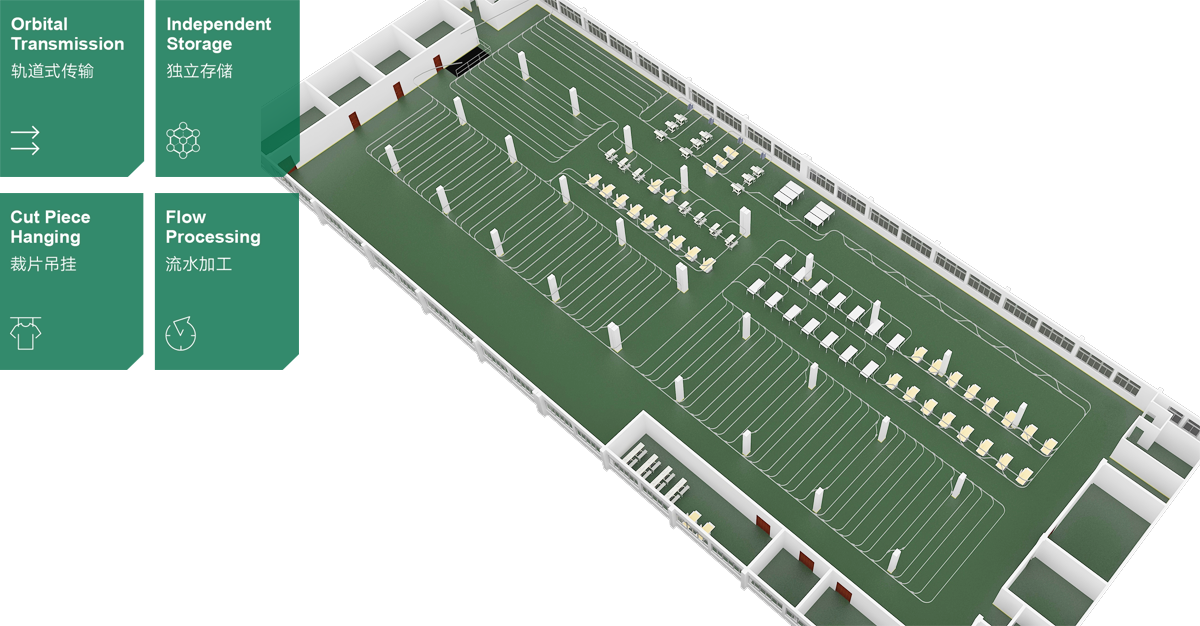

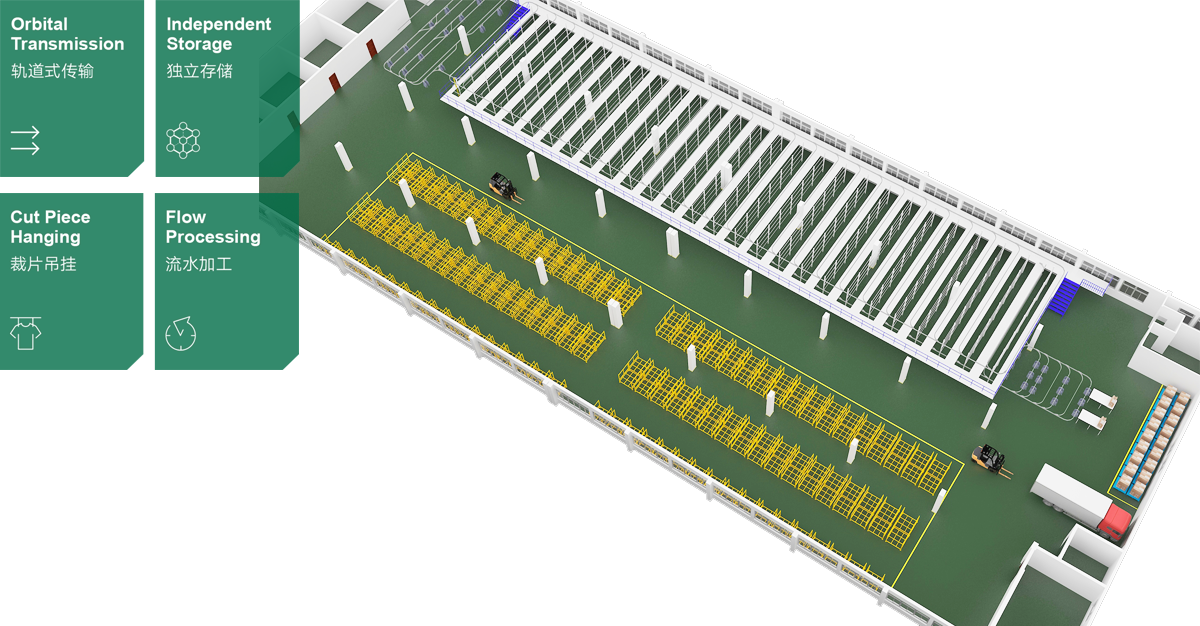

Workshop process layout planning

Cost budget

Engineering construction management

GSD standard working hour system

PAS production line data balance system

MES garment production management solution

IRCS intelligent name system

ITMS Intelligent Tools Management System

Intelligent assembly line

Intelligent conveyor system

Auxiliary equipment series

The cutting workshop is divided into a storage system, a cutting system and a cutting processing area, which are transported to the sewing workshop through the cutting and processing area to the piece supermarket.

After the pieces arrive at the sewing workshop, they are sent to each assembly line through the piece sorting system. After completion, they are sent to the post-finishing process through the manual hanging system.

After the finished product is finished, it will enter the warehousing workshop through manual nailing, hot stamping, hot stamping, inspection and matching.

The storage center is divided into three-dimensional storage and mixed storage. The finished garments are hung to the storage area, and then sorted by intelligent sorting system, automatically packaged and classified.

CopyRight © 2019-2020 All Rights Reserved. Suzhou Chijiu Energy Saving Electric Co., Ltd.

ADD:Tonggang Road, Haiyu Industrial Zone 2, Changshu City, Jiangsu Province TEL:0512-52583998